A global automotive products manufacturer uses our rapid rightsizing approach and rapidly achieves higher quality, less scrap, better on-time delivery and faster inventory turns. Rightsizing initiative pays off with $8 million in savings generated in just 180 days.

A global manufacturer and distributor of specialty tires and wheels spent several years in growth mode. Later, a significant drop in customer demand led to excess capacity, high inventory levels and cost issues. This drop, combined with inefficient manufacturing and distribution processes, limited planning and scheduling capabilities, resulted in the “perfect storm.” Productivity was low, quality was unacceptable, and inventories grew.

To turn this around, TBM focused on establishing quantifiable goals, improving the production & distribution footprint, and identifying the root causes of the issues.

Rapid rightsizing was the best solution in order to:

Challenge: After several years in growth mode, a significant drop in customer demand led to the “perfect storm.” Productivity was low, quality was unacceptable and inventories grew.

The client reduced its distribution and manufacturing footprint by consolidating distribution centers from 18 to 10 but needed assistance establishing an effective workflow within a smaller footprint.

We discovered that their root causes of low productivity were quality and rework. We also analyzed planning and scheduling processes to align inventories and operations with true customer demand. Batch processing was identified as an easy target for improving productivity. With multiple stamping operations that fed into welding and paint areas prior to assembly and shipping, inventory was piling up between every process.

Solution: TBM Consulting Group was engaged to help the client work more efficiently within a reduced footprint, drive down working capital, and redesign the production and distribution processes

We made several key adjustments to improve profitability and get back on track:

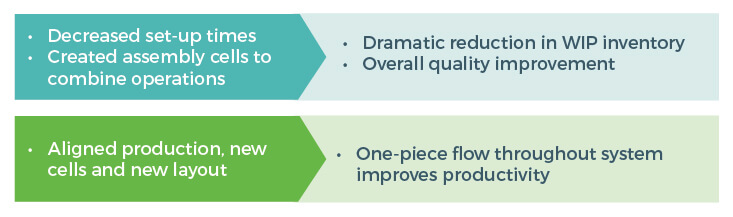

- Decreased set-up times in the stamping and welding areas

- Created assembly cells to combine multiple operations into a single cell

- Integrated a leak test operation at shipping prior to assembly, which reduced the work-in-process inventory and led to an overall quality improvement

- Aligned production, new cells and new layout to enable one-piece flow throughout the operation, improving productivity

- Developed collaborative planning and scheduling process for key customers

- Adjusted the demand and supply planning processes used to plan resources, capacities and outside supply requirements

Results: In just 180 days, the client generated over $8 million in annualized savings, resulting in over 20x ROI.

The manufacturing facility now produces a replacement immediately when a product ships. Profitability is up with sizeable improvements in quality, scrap, on-time delivery, labor efficiency and inventory turns.

Results included:

| Metrics | Before | After |

| Inventory | $30M | $21 M |

| Scrap (% of sales) | 1.35% | 0.5% |

| Distribution costs (% of sales) | 4% | 1% |

| Productivity (units/person/hour) | 5.75 | 6.83 |