In September, I had the opportunity to return to Asia for the first time in several years. I presented at the 2022 Vietnam Footwear Summit on the topic of Operational Excellence for Profitable Growth and Sustainability.

For this industry, in this region, it is truly an exciting time. While the footwear manufacturing industry in Southeast Asia is in no way immune to the recent obstacles impacting manufacturers across the globe, it is in an enviable position. The market is expected to continue to grow at a rate of 6% or more over the next five years. And the region itself is poised to continue to ride the wave of expansion as organizations chase low-cost labor and look to relocate away from China in particular.

The pathway to growth is clear and the rising tide will likely lift all ships.

Growing isn’t necessarily winning.

But that in no way means that organizations can afford anything less than vigilance when it comes to ensuring their growth is both profitable and sustainable. Inflation, supply chain disruptions, and increasingly complicated environmental and social regulatory demands will be strong headwinds cutting into productivity and profitability and making it more challenging to meet the aggressive deadlines of the fast fashion sector.

Companies that wish to win by capturing a bigger share of the revenue opportunity than their competitors and by ensuring their bottom line grows twice as fast as their top, will need to be flexible, responsive, and, most importantly, fast. As we like to say at TBM, speed wins every time.

3 Keys to Faster, More Profitable, More Sustainable Growth

Whether you are operating in the footwear industry in Southeast Asia, or any other industry in any other region of the world, operational excellence will separate the winners from the losers. Here are three keys to ensuring speed, flexibility, and responsiveness in the current operating environment.

1. Invest in effective relocation and network design planning to prevent downstream delays.

Companies that are expanding or realigning manufacturing operations to take advantage of growth opportunities obviously are motivated to get their plants up and running as quickly as possible. It is important to remember that speed is not the same thing as rushing in this situation. Indeed, structured thinking, thorough relocation risk analysis, and proper planning at the outset will set the stage for a sustainable speed advantage later so companies can avoid delays during the transition and downstream when operations are up and running.

We helped one company develop a rigorous, methodical framework for analyzing candidate countries for relocation. This included balancing the benefits and risks of any given location, such as geopolitical risk, tariff risk, labor costs, macroeconomic factors, ease of doing business in the region, and local incentives. The framework included a critical path relocation move plan and timeline. Using this process, the company opened its new plant 30 days ahead of schedule. This was a huge win considering the typical delays of six to 12 months on its past relocation projects.

Ensuring proper plant setup is just as critical as selecting the right country and having a solid transition plan. This is the time to take advantage of the opportunity to start with a blank slate. You can layout assembly lines and work cells to ensure the greatest flexibility and least waste. We worked with an organization to develop a detailed facility layout for 600 employees that improved material handling and reduced the distance traveled for all products by 50% compared to previous locations. When the new plant opened, there were zero disruptions to customer deliveries. The layout has since become the best-in-class standard and blueprint for all future greenfield plant relocations, ensuring all new facilities are engineered to compete on speed and efficiency, regardless of how future demand contracts and expands

2. Reduce lead times across the value chain.

The more quickly and efficiently you operate during every step of your process, the lower your costs and the faster you get to market and into your customers’ hands. Quality also improves because it takes less time to identify and correct errors. In short, speed makes you more attractive to your customers while making you more profitable at the same time.

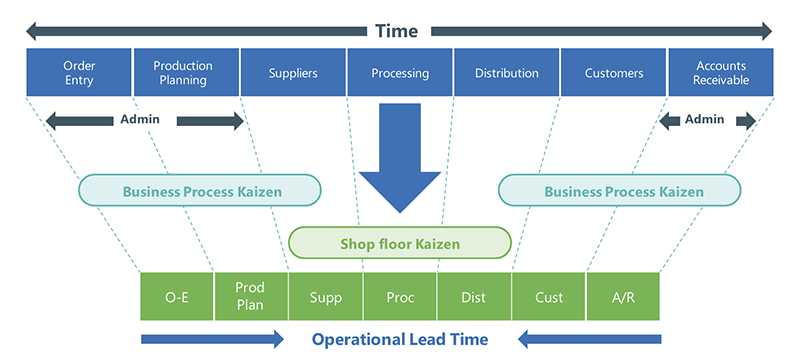

Identify areas to speed up procedures by looking across the entire value chain, beginning with taking orders all the way through collecting payments. If something you are currently doing is not adding value from your customer’s viewpoint, then the process should be changed, streamlined, or, if possible, eliminated.

Shop floor processing typically provides the greatest opportunity to reduce unnecessary non-value-added steps simply because this phase of the value chain ties up the greatest concentration of assets, including people, floor space, and equipment. Additionally, because this step lies at the center of the value chain, shop floor improvements often have a ripple effect, inspiring additional gains and time savings both upstream and down.

Use OpEx to Reduce Lead-Time Across Your Entire Value Chain

A management system can help companies more quickly take the right steps to maximize operational efficiency and reduce lead times. By tying strategic corporate goals to daily activities for people at all levels of the organization, such a system aligns the entire team and empowers everyone to solve problems at the point of impact for faster, better resolutions.

When Nike was struggling with its suppliers’ missing delivery dates and failing to hit cost and quality targets, the company worked with us to create and implement a global supplier assessment and lean operating system for its suppliers. Among the suppliers choosing to implement the system, defect rates were 50% lower, delivery times were 40% shorter, and factory productivity increased 10-20%. The time to introduce a new product to market fell by 30%, giving Nike the edge it needed to stay a step ahead of its competitors.

3. Take advantage of ESG.

While controversial, ESG (environmental, social, and governance criteria) is a common topic among investors, consumers, and employees - and companies have to determine how to incorporate it into their value and risk profile. When companies decide which elements of ESG they want to address for the specific purposes of better ratings and compliance with increasingly stringent regulations, they may find that better ESG performance comes naturally as a result of operational excellence.

For example, as companies work to create faster, more efficient processes, the processes become inherently better and safer for the environment as well as for the employees that perform the work. The processes require less time and energy. So, they are more cost-effective. And they are typically more employee-friendly, which can translate into less absenteeism and attrition, greater productivity, and lower hiring and retraining costs. Good ESG scores may also result in better access to capital and more favorable loan conditions, which are increasingly important in today’s high inflation environment.

Whether ESG is the driver or the outcome, the effect on speed and productivity is the same. Companies that take the waste out can more quickly meet their customers’ needs and will outperform their competitors in any market conditions.

Speed wins every time.

Whether you are grabbing share in a growing market or taking share from your competitors in a contracting market, the companies that win are those that can most quickly, cost-effectively, and reliably get products to market and into their customers’ hands. Regardless of industry or economic conditions, the speed, agility, and flexibility that come with operational excellence will position companies for sustainable top- and bottom-line growth. And it will help them attract the customers, employees, and investors they need to take their organizations to the next level of success.