Be ready for daily supply chain, freight, and labor disruptions. And keep your operations priorities on track.

For the past 24 months, TBM experts have been sharing strategies and helping clients develop and implement future-proof supply chain strategies and human capital management plans designed to combat the sourcing and labor issues exacerbated by the pandemic. These solutions—strategies like dual sourcing, alternative components, multiple agreements with logistics partners, and revamped compensation and promotion practices—can and do go a long way in reducing risk and increasing flexibility. But they can’t fully eradicate Murphy’s Law. And in today’s volatile business environment, it’s not a matter of if another disruption will occur; it’s a matter of when. All it takes is one unforeseen glitch in supply, fright, or labor force to derail the day’s production schedule, causing teams to scramble to adjust, and negatively impacting output, costs, and margin in the process.

That makes a good Plan B imperative. When something goes wrong, having an action plan at the ready can help supervisors and line leads turn on a dime, optimize the resources they do have available, and minimize the operational pain of the disruptions.

Here are five ways to put your Plan B in place:

- Stay ahead of the issues through S&OP.

Back when the pandemic first began, TBM encouraged manufacturers to step up the cadence of S&OP meetings and to have more frequent discussions around expected demand and the ability to profitability meet it. In challenging times, regular S&OP helps you foresee potential disruptions and avoid last minute reactions.

Times are still challenging, and we have not backed off our recommendation. Manufacturers need to keep developing and prioritizing the process rigor for strengthening S&OP processes and prioritizing regular discussions around capacity planning, scheduling, inventory management, and safety stock. If you have made overarching changes to sourcing strategy or your network over the past two years, then these conversations can help you track the effectiveness of new policies and identify where additional changes may be in order. - Create an escalation plan.

The sooner you know about an impending disruption, the more prepared you can be to minimize the impact on operations. While S&OP processes are the overarching catalyst to this foresight, an escalation plan is another critical tool.

It should start with improved supplier and freight carrier relations and ensuring your partners communicate with your purchasing as soon as they suspect a delay in delivery dates. Purchasers, if they cannot resolve the issue in a designated amount of time, must report the problem up the chain of command to the planners and schedulers and ultimately to the customer service team who will inform the customer. This process helps prevent last-minute reactions when the issue becomes a crisis, and it allows operations teams to plan in advance and adjust production schedules accordingly. - Be ready to make informed allocation decisions.

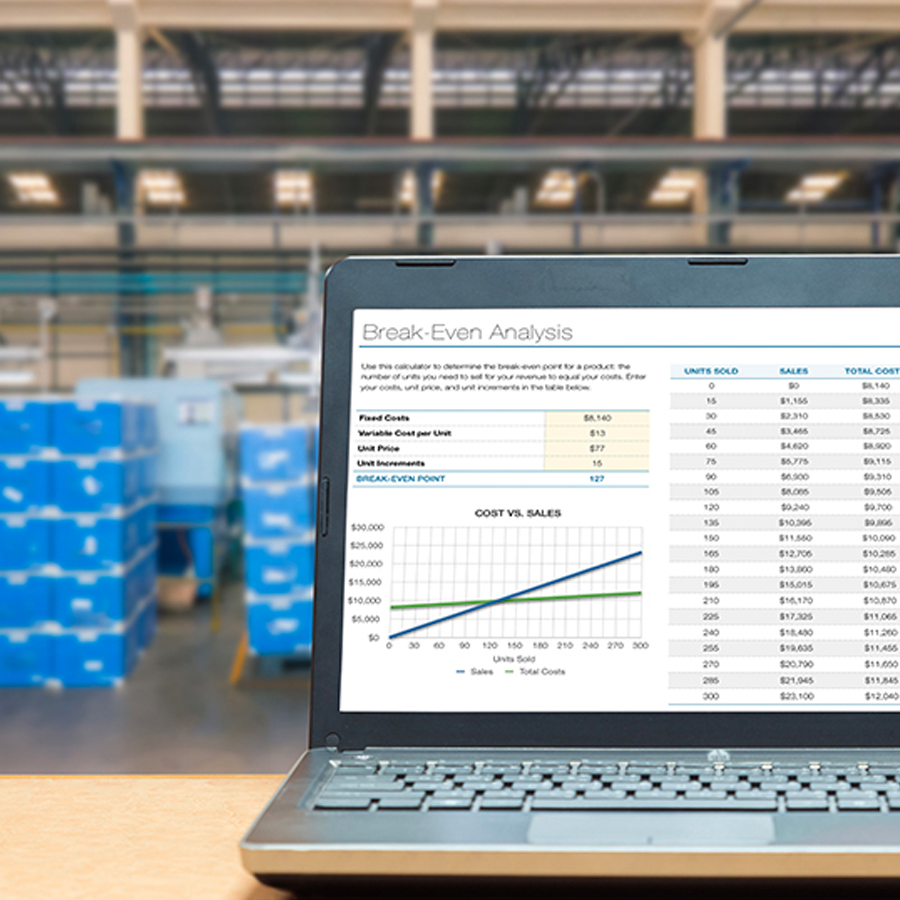

When material and labor shortages occur, despite your best efforts to prevent them, allocation becomes necessary. To make quick and good decisions around which products to make and which customers to serve with your limited capacity, leaders need increased visibility and insight into network costs. Specifically, they need to understand margins by product and customer and total cost to serve. Without this information, decisions become emotional and internal debate wastes even more precious resources and time.

We work with one organization with a complex network and multiple capacity constraints. While the company had robust S&OP processes, it lacked the financial understanding of its network. By implementing key changes to its existing systems, we helped the organization gain a holistic view of its total costs. Leaders can now make faster, more informed decisions across the network and easily prioritize high-margin items if and when allocation becomes necessary. - Improve operational flexibility.

Knowing which products to prioritize is one thing. Quickly and cost-effectively putting your organization in a position to produce those items is another. And that’s where operational excellence comes into play. Manufacturers that excel at line balancing, sequencing, standard work, and other processes designed to optimize productivity will have an edge here. Quick changeover times are also key. By addressing tooling constraints, optimizing work cell layouts, and modifying equipment to handle different products, companies can build in operational flexibility that enables faster production line switches.

We partnered with one manufacturer to specifically improve change over times by implementing a stocking strategy that supports sequencing common setups. We helped implement modifications in scheduling practices to further reduce the time required for line set up. These relatively simple changes had a significant impact on throughput and productivity and have positioned the company to more quickly respond to future disruptions. - Optimize access to workforce skills.

There is perhaps nothing more frustrating for a manufacturer than having the plan and materials and finding you don’t have the people to execute. Manufacturers have gone to great lengths to keep their lines staffed, including paying premiums, bussing people in from other locations, and developing relationships with multiple staffing agencies. One company we work with implemented a six-month contract with current employees to increase their pay in the short-term and help prevent turnover and absenteeism during one of its most challenging periods. Nevertheless, daily workforce shortages still happen. And companies must react in the moment to do the best with what they have.

Again, visibility and information are key to understanding the operational priorities and the cost implications of allocating the people you do have to the most critical tasks. Obviously, the more training and cross-training you do, the more options you will have to move people around to fill gaps. But to make those changes, supervisors and line leads need to see at a glance what skills are available on any given day. Maintaining an up-to-date skills matrix is an easy way to empower these leaders to make effective fast decisions.

A skills matrix will also point to areas where your bench strength may be weak and where you need to invest in additional people or training. And it can help illuminate labor issues that may require a more strategic solution. One regional manufacturer we support was facing such significant staffing issues that it ultimately decided to close a site. An in-depth network study and a deeper understanding of skills, labor availability, and cost structure helped the organization put its available resources to the best possible use.

Focus On What You Can Control

Ideally, your longer-term sourcing and human capital management strategies will help reduce shortages and risk and prevent the last-minute reactionary changes that lead to loss. But if and when disruptions do occur, having a good Plan B and the flexibility to execute it quickly can help save the day and protect your operational agenda. Ultimately you can’t fully control the supply chain and labor force and all the risks and factors at play. But you can control your response. Implement and finetune processes that can help you prepare for anything and flex in the best ways for your business. And get through your next disruption with more confidence and less operational pain.