Squeezing out the waste to make more space in shipping and distribution.

Today the company has abandoned high-volume, batch manufacturing and has fully embraced product variation and smaller order quantities. WIKA’s 210,000 sq.-ft U.S. headquarters and factory in Lawrenceville, GA, can now assemble and deliver over 50,000 different product configurations in a few days. It also ships 1,400 different stock items the same day that orders are received. Offering such superior service to its customers gives the company an edge compared to overseas competitors in terms of cost and customer responsiveness.

Challenge: The company’s distribution department needed to support a globally competitive market strategy by reducing order-to shipment lead times and preparing for a 25% increase in sales volume without adding people and floor space.

To guide the department’s transformation, WIKA worked with TBM Consulting Group to develop a long-term plan that would get the operation where managers wanted to be. These goals included:

- A greater than 30% improvement in productivity

- Reducing shipment errors by half, improving on-time delivery above 95%

- Doubling throughput without any increase in floor space

Meeting these objectives would help the shipping department cope with a projected 25% increase in sales. In addition, customers could become more comfortable purchasing in lower quantities.

Solution: TBM conducted a strategic visioning session, mutually reinforcing kaizen events and related projects. Cross functional improvement teams applied lean principles to simplify order picking, packaging and shipping processes. The changes will also streamline product flow and improve inventory management.

The first thing that WIKA did to improve its shipping operation was to create standard packaging cells and four standard pack sizes—down from 20. Each packing station had been different from the next one. Some had scales, and some didn’t. Some had taping machines, and some didn’t.

WIKA shipping and picking personnel participated in a weeklong kaizen event where they designed their new work cells. They tested improvements with cardboard mockups, putting everything within easy reach and working out any kinks before building the final workstations. As a result of this change, standardized work and other improvements, work-in-process inventory in packaging immediately fell from two hours to less than 30 minutes.

“The flow has improved unbelievably. The ergonomics have improved incredibly and the people love it,” says Zielinski. Because they were so significant, these changes to the material flow did require a $100,000 capital expense for the installation and setup of new conveyors. Promising a 10-month payback, because the cost justification plan detailed how the investment supported previous and planned improvements in the shipping department, WIKA’s CEO approved it the next day.

WIKA next attacked the flow-rack picking area. The team re-slotted the entire flow-rack area. They moved fast-moving items closer to the pack and ship area. They moved the heavier gauges to waist height where they would be easier to handle and reduced the standard tote quantity from 18 to 12 units (the largest order quantity),cutting the total weight from 38 to 26 lbs.

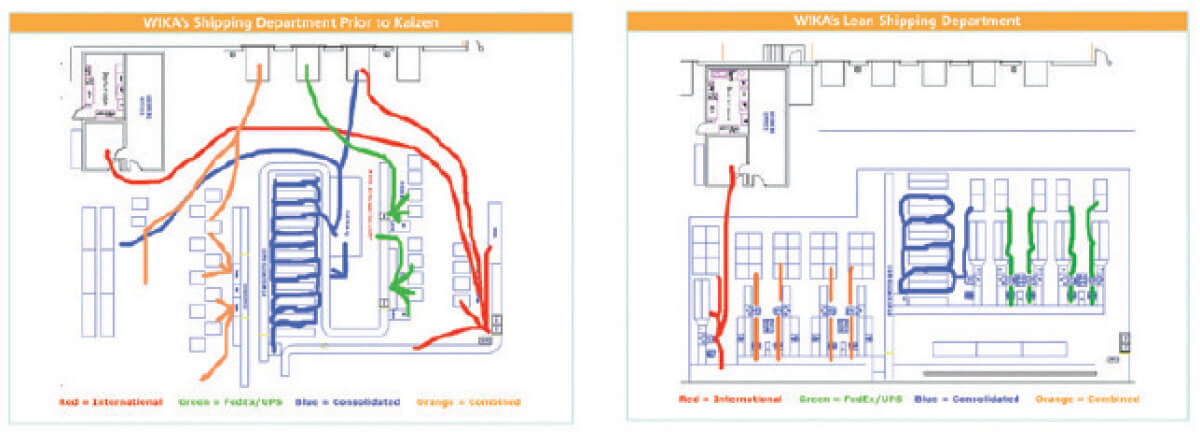

This diagram shows the redesigned material flow through WIKA USA’s shipping department. From manufacturing and inventory storage areas, FedEx/UPS shipments (green), consolidated orders (blue), combined shipments (orange) and international shipments (red), flow directly to packaging stations and out the dock doors (top).

Results: Less than one year into a three year plan, WIKA had improved productivity by 17% and reduced pick, pack and ship errors by 43%. This will ensure that WIKA can meet additional sales volume and change from multi-line orders to single-line orders.

The flow-rack team also re-designed the labeling system. The old labels had identical black numbers printed on a beige background. They assigned specific colors to each part number and located parts so that there were no like colors or similar part numbers together. This reduced opportunities for error during put away and order picking. As a result of this effort, the shipping department achieved double-digit percentage increases in the number of lines picked per day and per hour.

“If you don’t do all of your homework and assignments from the first kaizen, you’re really going to suffer when you go to the next one.”

—Jim Zielinski, Distribution Manager, WIKA USA.