Plant turnaround implements Lean to rightsize their facility for a smaller footprint, improve quality, faster delivery, and a rapid return to profitability.

A facility consolidation between two plants with completely different operating approaches created severe capacity constraints and service and productivity issues.

First, we established quantifiable goals and objectives linking operational metrics to financial performance. We immediately assessed the facility to identify the root causes of low productivity, quality problems, and rework.

The project team quickly realized that standard work was just one of the missing puzzle pieces. In order to address the quality issues, the team needed to get product moving more fluidly into the assembly area. By evaluating production constraints, the team was able to rebalance labor and create single piece flow throughout the line, thus reducing the amount of rework and errors.

Challenge: The company experienced unacceptable yields and downtime. The newly consolidated facility was struggling to meet customer demand, quality was suffering and scrap and rework were at unacceptable levels. There was no standard work in place, and the facility was losing money every week.

The next step was to implement the tools and processes for a management system that enabled accountability for daily performance at the shop floor level.

Created Daily Shop Floor Accountability By Implementing:

- Standard measures

- Daily management meetings

- Visual management systems on the floor

Solution: A 120-day project focusing on driving rapid improvements in service and quality levels, and immediately getting the facility back to profitability.

We implemented standard measures, instituted daily management meetings, and placed visual management systems on the floor. This helped establish expectations for the plant leadership, shop floor supervisors, and team leaders. The resulting standard work and daily management system helped change the production environment and created a more manageable cadence for the shop floor and the management team.

The client was able to return to profitability, align with ongoing changes in customer demand, and remain viable and competitive — prepared to emerge in a stronger position as the economy improves.

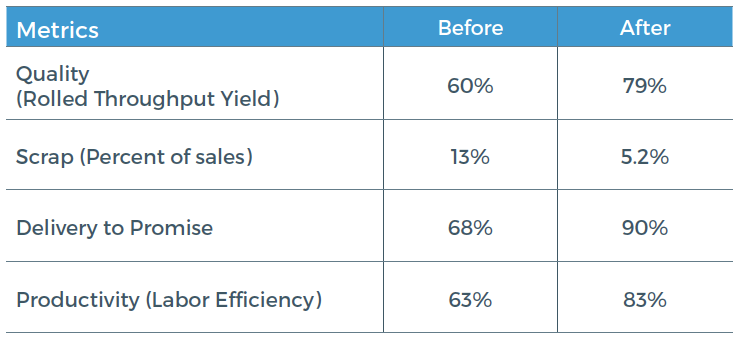

Results: In just 120 days, the client generated $5.6 million in annualized savings, resulting in a 15x ROI.

Rightsize Your Operations

Significant results. Fast.

Our rightsizing approach gives you the agility to adapt quickly to changing business conditions. Whether you’re already embracing a lean approach, or just thinking about it, Rapid Rightsizing will drive immediate results that include:

- Rapidly reducing working capital

- Identifying and eliminating hidden costs that consume cash

- Improving liquidity by quickly converting assets into cash

How we do it.

We send in dedicated project-based “SWAT” teams for short-duration projects — usually six months or less.

We focus on inventory, receivables, floor space, quality, and even energy consumption to find the cash you can’t see. Most important, we make sure that we leave you competitively positioned for long term achievements while meeting short-term objectives.

What results can you expect?

In most cases, we drive millions of dollars in annualized savings in six months or less. All our work is unconditionally guaranteed.