Robust management system helps rapidly growing food manufacturer return to profitability.

Rapid growth is exhilarating and challenging in any industry. Operationally speaking, efficiency gains and output improvements can hasten or boost earnings and delay capital expenditures that can siphon up precious cash. This case study details some of this work, shows how it has bolstered the company’s revenue and EBITDA growth, and underscores how important culture and a robust management system are to operational excellence.

The company’s minority owner, a private equity investment firm, asked TBM advisors to come in and help improve operational performance. Our efforts focused on two facilities. Both plants are situated in rural locations with an engaged employee base who want to contribute to the success of the organization.

Each facility is divided into two main areas: production and packaging. Packaging is further subdivided into three areas: flavoring, filling and final packaging. The production processes have mandatory “clean in place” requirements that force equipment shutdowns periodically for system sanitation. The sanitation process reduces the maximum efficiency potential to around 85%.

Challenge: Ingredient waste and plant operating efficiencies in the mid-60% range were hurting delivery dates and undermining margins.

From the beginning our efforts focused on the areas that would have the greatest impact on the financial success of the rapidly growing business. The primary issue in the newer facility was ingredient waste. Every day the plant was losing an average of 2,200 lbs. of flavoring ingredients. Because the process was sealed, the waste was invisible to machine operators. But it appeared in accounting statements as a large variance of more than $50,000 every month.

The company’s other facility was struggling to maintain efficiency levels higher than 65% on a consistent basis. As happens in many organizations, problems would arise and be fixed, then shortly reappear. The underlying causes were not well understood, and therefore never fully resolved.

Working with a representative from the private equity firm, our initial assessment identified three major CI focal points:

- Leader standard work

- Eight-step problem solving and A3 reporting*

- A structured and tiered daily management system

Engaging every level of operations management, we designed the training material to introduce the problem-solving concepts and process steps, and then apply them to real-world issues. Each training participant, for example, chose from the initial list of problems, or brought one from their areas, then worked through the eight-step process to create an A3 to address the problem.

Solution: Reintroduction of lean practices and the application of structured problem-solving methods in conjunction with a more robust production management system.

Following this training, in the first plant we attacked the ingredient waste issue by facilitating a week-long kaizen event. The kaizen team included a representative from the vendor who was instrumental in helping to identify the root cause of the issue. Through observation and analysis, the team discovered that the design of the outlet on the bottom of the wet ingredient container was preventing a significant quantity from exiting. It was like ketchup clinging to the side of an upside-down bottle.

At the second facility the primary focus was on establishing a more robust management system. When we started, the leadership team usually met each morning for 15-30 minutes to review current production status and address any issues. The meeting took place in a conference room in the office far removed from the plant floor. In addition, handoffs between shift supervisors occurred in an ad hoc fashion, and production performance for each line wasn’t being measured in the most meaningful way.

TBM helped implement a much more structured production management system. Specifically, with our assistance, area managers began tracking and reporting performance on SQDC (safety, quality, delivery and cost) boards, and recorded specific issues on separate hour-by-hour boards. Site leaders and the area supervisors began discussing these issues at a daily review meeting, which is now held in a quiet room just off the production floor.

While the management system changes and problem-solving techniques were piloted at one of the two facilities, company managers then shared the practices and lessons learned with their counterparts. Much of the organization’s success can be attributed to this willingness to share and create a learning culture.

Results: Elimination of raw material waste and a 4- to 5-point efficiency improvement, which made a significant contribution to the company’s return to profitability.

Despite some initial skepticism, management was willing to try new approaches and see if they worked. They didn’t just try something for a couple of days and then back away because it didn’t have an immediate impact. They would stick to process changes for 3-4 weeks, which is long enough to work out the kinks, form new habits and see the results, before going ahead and tweaking the process further. Such an attitude and approach is essential in a fast-growing startup business, or in any manufacturing operation that continues to stay vital and make significant contributions to the company’s sales and profit growth.

In addition to day-to-day inventory management practices, successful deployment must also optimize the management practices that feed into and influence inventory decisions.

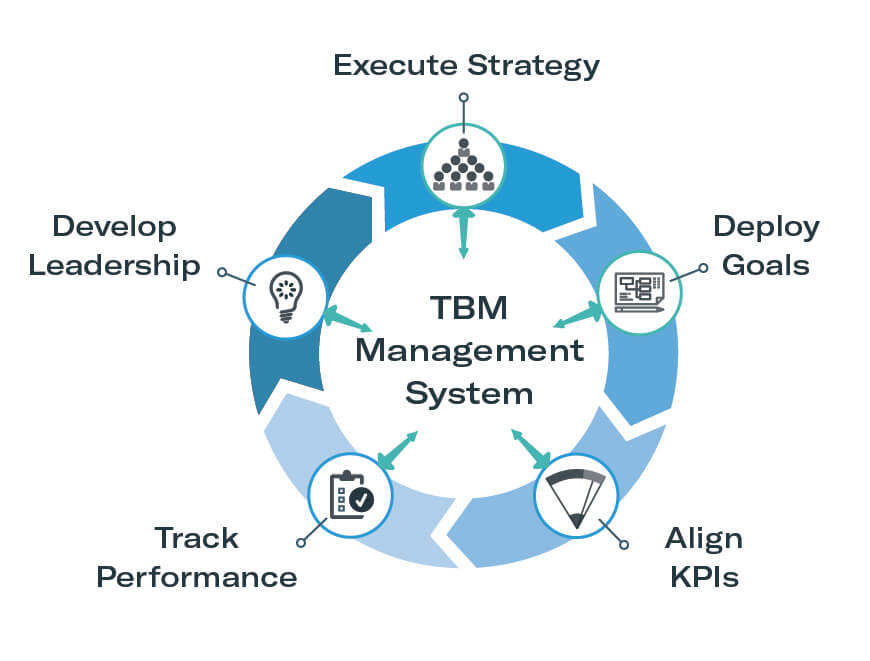

What is a Management System?

A Management System is an integrated set of processes and tools that help company leaders develop an effective strategy and annual objectives, translate those goals into operational actions, and monitor progress. Such a framework empowers managers and employees to drive process improvement on a daily basis in alignment with the organization’s strategic direction.

The benefits of an effective management system include:

- Well-defined and understood performance metrics

- Strategic objectives cascaded to all levels of the organization

- Cross-functional teams that work together on company-wide goals

- Increased management and employee engagement

- Faster achievement of key objectives